The Compressor Technique Service Division at Atlas Copco supports a continuously improving and growing range of machinery and models, making it challenging for their well-trained technicians to be an expert at troubleshooting all equipment and technologies. Moreover, the company has expanded across the globe and grown considerably, creating a great challenge in keeping their knowledge organized and managed systematically. When the opportunity came to evaluate different software options for organized knowledge, they took it and soon chose Dezide.

Atlas Copco Compressor Technique transfers skills faster with Dezide

Read about how we helped Atlas Copco Compressor Technique better transfer skills to new generations of field technicians

Significant reduction in troubleshooting time

Much easier access to information

Increased customer satisfaction

About Atlas Copco Compressor Technique

Atlas Copco Compressor Technique is a leading manufacturer of efficient and cost-effective air compressors for all industries. Atlas Copco was founded in 1873 in Sweden and the Compressor Technique business area was created in the early years of the 20th century when the first compressors, tools, and rock drills were manufactured. Atlas Copco group employs 39.000 people. The Compressor Technique global headquarters is located in Antwerp, Belgium.

Hidden knowledge and traditional documentation limited the ability to fix problems on first visit

Atlas Copco Compressor Technique Service Division has supported a wide range of machinery and models over a long period of time. This made it impossible to have sufficient knowledge about all possible equipment, technologies, and configurations. Moreover, the company has expanded across the globe and grown considerably and the combination of a big complex range of products and impressive growth made training and knowledge management very challenging.

It was difficult and time consuming for on-site technicians to find documentation that could help them, and when they found a document it was often a very long PDF file with more than 20 pages, which meant it took a lot of time to browse for the exact piece of content that could help out in the given situation.

Choosing the right guided troubleshooting system

The Atlas Copco Compressor Technique Division explored different solutions within the troubleshooting space. They required a system that would grow with the business while being easy-to-use as the main users of the tool are service technicians working at customer sites. This requirement eliminated many vendors, and they were convinced that Dezide’s causal AI solution could solve their challenges related to easy access to relevant information on the spot and increased knowledge sharing.

“Without this digitalization, we would have continued to work as before relying heavily on technicians being communicative enough to phone in support when/if needed”

“We have looked at other suppliers of similar software but chose Dezide because of the simplicity of the tool combined with sufficient functionalities like data collection & causal Bayesian Network technology.”

The benefits

As growth capabilities and user-friendliness were the main requirements for the Atlas Copco Compressor Technique Division when deciding on the most suitable knowledge management software, some of the most important features of the system were:

Responsive and scalable

Having a scalable and responsive tool is essential when handling knowledge about a wide range of products. There is no doubt that Atlas Copco greatly appreciated this feature when selecting their troubleshooting tool.

Easily manageable from a content maintenance perspective

Continuous innovation and machine improvement created the need for Atlas Copco to update and manage content in an easy way. With Dezide they can update this content whenever they need it.

Strong language support

Worldwide service support results in the need to manage content in many different languages. With Dezide, Atlas Copco can handle as many languages as needed.

Software integrations for IoT and data collection

Dezide perfectly integrates with the IoT and data collection applications of Atlas Copco, enhancing the standardization of processes and transferring diagnostic results to the field users.

Atlas Copco Airpower explored other solutions in the knowledge management space, and they required a system that would grow with the business which eliminated many vendors when this need was combined with a desire for a software solution that was easy-to-use.

The main users of the tool are the field service engineers (FSE) working at customer sites. They use the tool when they are alone on-site and don’t know what to do or when they need additional information/assurance.

“We strongly believe that training people and having a good working relationship between technicians and technical support is still necessary. Dezide complements this and strengthens the service delivered to the customers”

Operational model

Atlas Copco Airpower has 1,2 full-time employees building content using dedicated sessions with machine experts to capture the troubleshooting information and turning it into guides and articles. Once the information is in the system, the experts validate it which often results in a face-to-face session. After this validation, the content is made available for field technicians.

Input from field technicians is handled by the same content managers and if needed, this is validated by the content expert before making the adjustments available for all technicians.

Translations are made by the local technical support teams i.e. in China. After they translate the content, the content managers publish the content to the technician portal.

One of the content managers is located in the knowledge center in the US and the project manager/second content manager is located at the Compressor Technique main office in Belgium maintaining regular contact by email and phone.

Every month a review meeting is conducted to assess performance, content production and overall coordination.

“Our technicians enjoy the quick and easy way of finding relevant information”

Atlas Copco Compressor Technique transfers information and skills faster with Dezide

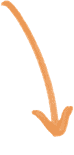

The Dezide project has allowed Atlas Copco Airpower to start working in a more structured way concerning machine troubleshooting. The system facilitates documenting what can go wrong on a machine and information about how to fix it. It really makes you think about how to troubleshoot issues when breaking the issue down into causes, probabilities, actions, and costs using causal AI.

Next to this rich knowledge source, technicians enjoy a quick and easy way of finding relevant information. The usage of Dezide has allowed a better transfer of information and skills, so the technicians feel better supported, resulting in fewer repeated visits and escalation of cases.

Also, training new personnel has become much easier as knowledge is now available in an easily accessible digital form. This means that training time has been reduced significantly.

Ultimately, customers experience a quicker resolution of the problems, resulting in increased customer satisfaction.